Galvanization, the process of applying a zinc coating to steel or iron to prevent rusting, has various advantages and disadvantages. Below is an overview of these pros and cons, with a focus on the keywords: New Taipei galvanization, Shulin galvanization, New Taipei welding, Shulin welding, and Shulin laser cutting.

Advantages of Galvanization

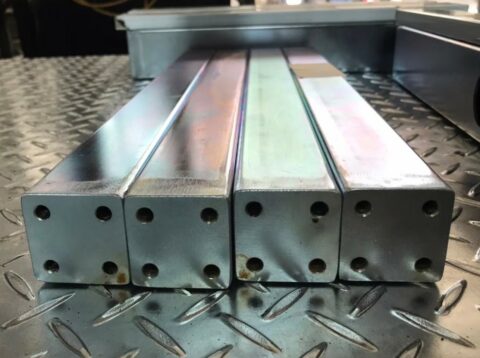

- Corrosion Resistance: The primary advantage of galvanization is its ability to protect metals from corrosion, significantly extending the lifespan of steel and iron products.

- Durability: Galvanized coatings are tough and abrasion-resistant, providing long-lasting protection even in harsh environments.

- Cost-Effectiveness: Compared to other protective coatings, galvanization is relatively inexpensive and offers a good return on investment due to its long service life and low maintenance requirements.

- Comprehensive Protection: Galvanization coats the entire surface, including edges, corners, and hard-to-reach areas, ensuring complete protection.

- Fast Application: The galvanization process can be completed quickly, making it suitable for high-volume production.

- Maintenance-Free: Galvanized products require little to no maintenance, reducing long-term costs and effort.

Disadvantages of Galvanization

- Appearance: The zinc coating can have a rough or uneven appearance, which may not be suitable for applications where aesthetics are important.

- Thickness Limitation: It can be challenging to control the exact thickness of the zinc coating, which may affect the performance in certain applications.

- Temperature Sensitivity: Galvanized coatings can degrade at high temperatures, making them unsuitable for high-temperature applications.

- Potential for Hydrogen Embrittlement: During the galvanization process, hydrogen can be absorbed into the metal, leading to embrittlement and reduced ductility, especially in high-strength steels.

- Initial Cost: While galvanization is cost-effective in the long run, the initial cost may be higher than some other coating methods.

Keywords: New Taipei Galvanization, Shulin Galvanization, New Taipei Welding, Shulin Welding, Shulin Laser Cutting

Applications and Integration

- New Taipei Galvanization: Businesses in New Taipei City can leverage galvanization to protect steel structures used in construction, infrastructure, and various manufacturing sectors.

- Shulin Galvanization: In Shulin, galvanization is particularly useful for local industries involved in producing outdoor equipment, automotive parts, and electrical components, where corrosion resistance is critical.

- New Taipei Welding: Welding in New Taipei City, including the use of galvanized materials, ensures the creation of strong, durable structures for construction and industrial use.

- Shulin Welding: Shulin-based welding services benefit from using galvanized steel, providing enhanced durability and longevity for welded joints in various applications.

- Shulin Laser Cutting: Shulin’s laser cutting services can precisely cut galvanized steel, allowing for the production of custom parts and components that maintain their corrosion-resistant properties.

Conclusion

Galvanization offers numerous advantages, particularly in terms of durability and corrosion resistance, making it a valuable process for various industries in New Taipei City and Shulin. However, understanding its limitations is crucial for making informed decisions about its application. By integrating galvanization with welding and laser cutting, businesses can achieve optimal performance and longevity for their metal products.

Keywords for SEO and Marketing:

- #新北鍍鋅

- #樹林鍍鋅

- #新北焊接

- #樹林焊接

- #樹林雷射切割