Why is Deburring Important? Introducing Shangbang’s Latest Equipment

The Importance of Deburring in Metal Processing

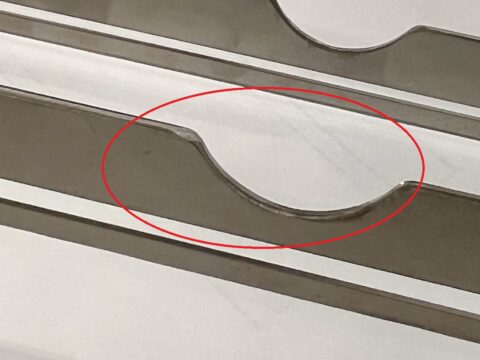

During metalworking processes such as cutting, stamping, and milling, sharp burrs are often left on the edges of materials. These burrs not only affect the appearance of the product but also pose safety risks, such as cutting operators or interfering with assembly. Additionally, untreated burrs can hinder coating adhesion, reduce product durability, and increase friction in precision machinery, affecting operational accuracy. Therefore, deburring is a crucial step to ensure product quality, user safety, and longevity.

Manual vs. Machine Deburring: Differences and Pros & Cons

Traditional manual deburring involves using files, grinders, brushes, or sanders to smooth the edges. While flexible and suitable for small-batch or uniquely shaped parts, it has significant drawbacks: it is time-consuming, inefficient, inconsistent, and can cause operator fatigue, leading to quality variations. In contrast, machine deburring offers stable, efficient, and consistent results, making it ideal for mass production, reducing labor costs, and ensuring uniform product quality.

Shangbang’s New “Brushed Roller Deburring Machine”: Features & Applications

Shangbang Steel has recently acquired a state-of-the-art Brushed Roller Deburring Machine, capable of high-efficiency deburring, hairline finishing, and random pattern polishing. Key advantages include:

- High Efficiency & Stability – Capable of continuously processing large volumes of workpieces.

- Multi-Function Integration – Simultaneous deburring and surface treatment to enhance texture.

- Precision & Consistency – Automated control ensures uniform results, eliminating manual errors.

- Wide Material Compatibility – Suitable for stainless steel, aluminum, black iron, and more.

This investment allows Shangbang to provide superior metal processing services for industries such as precision machinery, architectural decoration, furniture manufacturing, and electronics. Moving forward, Shangbang will continue to advance its technology to meet diverse market needs and deliver exceptional solutions to its clients.